Explore our image slider above to see our workshops for aluminum squeeze tubes, laminated tubes, and plastic tubes.

Reliable Collapsible Tubes Manufacturer

For over a decade, Junsam has been a prominent manufacturer of collapsible tubes, including aluminum tubes, toothpaste tubes, and plastic tubes. It is proudly based in China and serves clients worldwide. Our extensive experience and commitment to quality have solidified our reputation as a reliable and trusted manufacturer.

Our collapsible tube packaging advantage:

At the heart of our operations, we prioritize offering the best prices, the fastest lead times, and the most professional services in the industry. Additionally, we deeply care about environmental sustainability in packaging, ensuring our products align with eco-friendly practices.

Company Mission & Vision as a leading collapsible tube manufacturer

We aim to deliver top-tier tube packaging solutions that meet and exceed customer expectations. We envision a future where sustainable packaging practices are the norm, and our products play a vital role in fostering a greener environment for future generations.

Service

Our dedication to customer satisfaction drives us to provide personalized service, efficient delivery, and innovative solutions tailored to our clients’ needs. We believe in going the extra mile to ensure a seamless and reliable experience for every customer.

Awards & Recognitions

Our commitment to excellence and environmental sustainability has garnered industry recognition and accolades, showcasing our leadership in product quality and responsible manufacturing practices. These honors underscore our continuous efforts to be at the forefront of sustainable tube packaging solutions.

Contact us today to discover how our premium aluminum tubes, toothpaste tubes, and plastic tubes can elevate your packaging needs while contributing to a more sustainable future.

2024 Hot-Sale Collapsible Tubes & Related Products

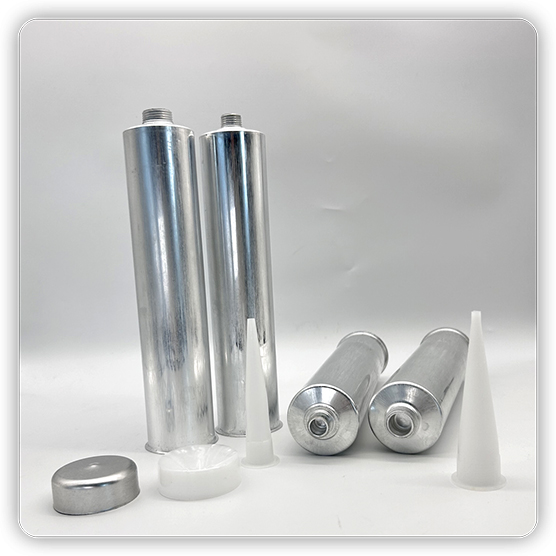

Aluminum Tubes

Plastic Tube Packaging

Plastic Tube for Cosmetic

Plastic tubes made of LDPE and HDPE materials are widely used in the packaging of cosmetic products.

Get a free quoteHDPE Plastic Tube

HDPE Plastic Tubes are recyclable, which appeals to environmentally conscious consumers and brands aiming for sustainable packaging solutions.

Get a free quoteDual Chamber Tubes for Cosmetic

Dual chamber tubes for cosmetics are designed for products that require two separate formulas to be stored without mixing until the moment of application.

GET A FREE QUOTEToothpaste Tubes

Aluminium Tubes Manufacturing Process

1) Extruding: the aluminum slug or flake will be extruded into tubes.

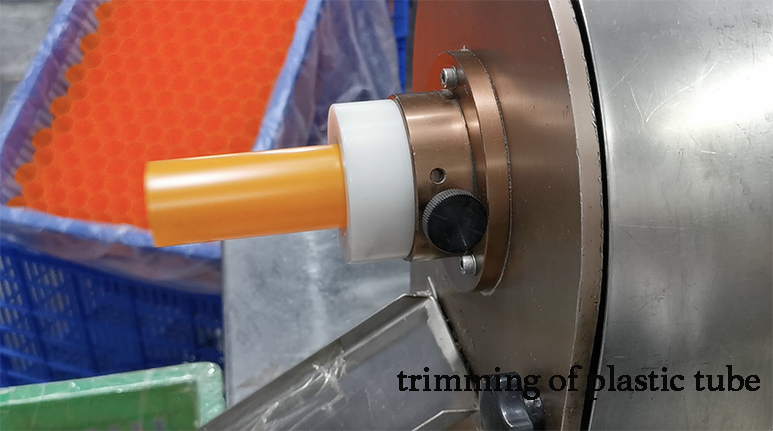

2) Trimming: the tubes will be precisely trimmed to custom lengths.

3) Annealing: the aluminum tubes are slowly heated to a certain temperature in the annealing furnace, maintained for a sufficient time, and then cooled at an appropriate speed.

4) Internal lacquering: this is a crucial step, which involves the uniform application of appropriate epoxy phenolic resin across the entire inner surface of the aluminum tubes

5) External lacquering: external lacquers, available in a theoretical spectrum of colors, will be applied to the outer base wall of the aluminum tubes. To optimize design performance, we offer valuable tips and suggestions. Should you embark on crafting a new design, we are eager to provide our expertise

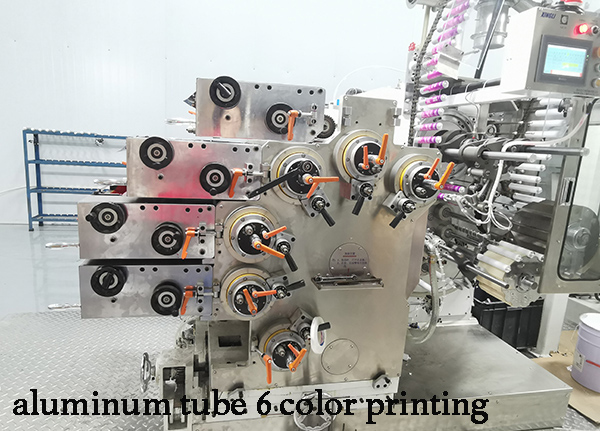

6) Printing: customized designs will be expertly transferred onto the external lacquering, utilizing our capability to print in up to a maximum of eight colors.

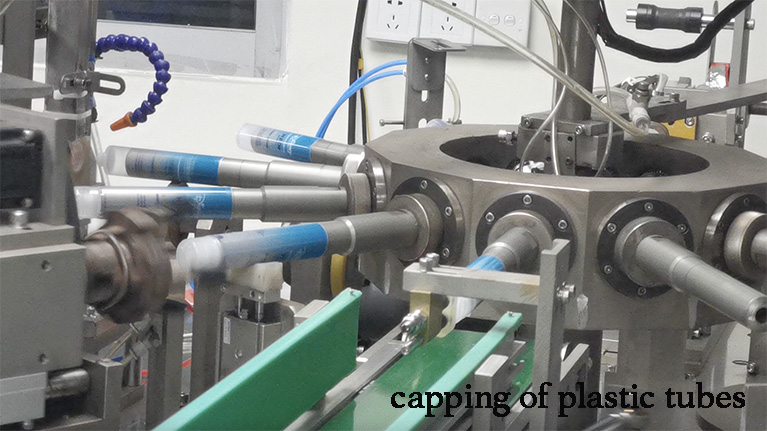

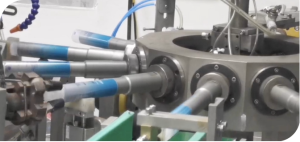

7) Capping: our facility is equipped with automatic capping machines that efficiently attach caps, thereby contributing to reduced lead times.

8) Latex: latex should be uniformly applied to the bottom of the aluminum tubes to enhance their sealing capability. However, the use of latex is actually optional for certain products.

9) Packaging: generally, the finished products are packaged in clean, sturdy corrugated cartons.”

Our image slider above showcases our capability for crafting various high-quality aluminum collapsible tubes

Plastic Tubes Manufacturing Process

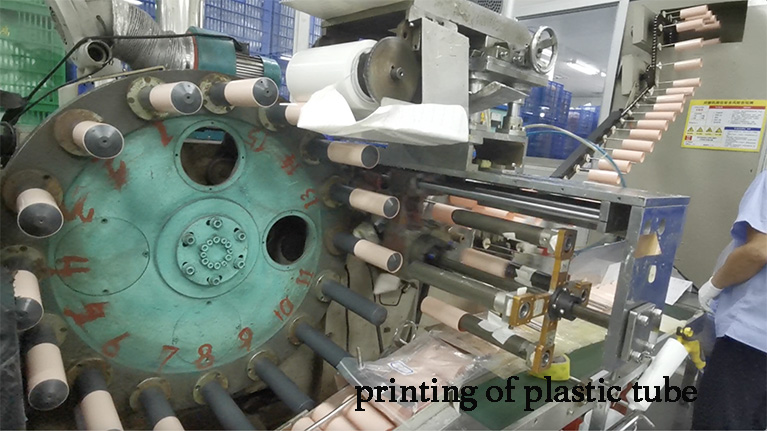

Want to see our plastic tubes? Check out the image slider above for a glimpse inside our squeeze plastic tube.

1. Extruding: it refers to the process of heating and extruding plastic, then pulling it through a specific die aperture to form a tubular plastic body of a certain length and thickness. This step is crucial in tube manufacturing as it determines the tube’s diameter, wall thickness, and overall uniformity. By controlling the extrusion speed and temperature, the quality of the tube product can be ensured.

2. Heading: it refers to the process of affixing the head and shoulder components to the main body of the tube.

3. Printing: custom designs can be applied to the base of the tube using a variety of techniques, including offset printing, silk screening, and hot stamping etc.

4. Coating: in the production of plastic tubes, the coating process ensures the durability and permanence of the printing on the tubes.

5. Holing & Capping: the nozzle is shaped by punching it into the extruded plastic, and the foil membrane will be adhered to the nozzle of the plastic tube, after which caps are automatically affixed to the tubes.

6 Sealing the tube at the end is optional and can be done according to customer requirements.

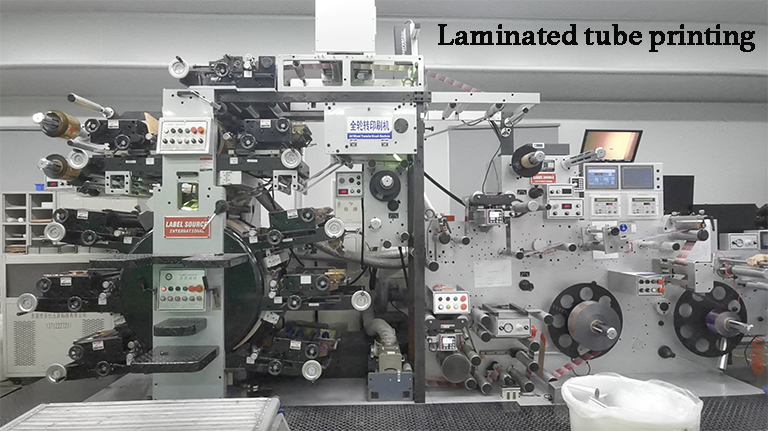

Laminated Tubes Manufacturing Process

Swipe through the image slider above to explore our laminated tubes.

Collapsible Tubes Application

Collapsible tubes, such as aluminum, plastic, and laminated, serve as a versatile packaging solution across multiple industries.

Aluminum Tubes for Food

One of the most common uses of aluminum tubes is in the food industry. They are often used to package ketchup, chocolate, mustard, cheese, animal food or nutrition, etc.

Aluminum Tubes / Plastic Tubes / Laminated Tubes for Cosmetic and Personal Care

The aluminum tubes and plastic tubes are widely used to package cosmetics and personal care products, such as hair dyeing, hand cream, lip balm, toothpaste, shaving gel, and shoe polish etc.

Aluminum Tubes for Pharmaceutical Ointment

Aluminum tubes are extensively utilized in the pharmaceutical sector for the packaging of ointments due to their superior protective qualities and ease of use.

Aluminum Tubes for Chemical

The aluminum tubes are usually used as packaging or containers of glue, adhesive, grease, lubricant, pigment, and oil paint etc.

Aluminum collapsible tubes we produce for hair dyeing never fail stability testing of inner lacquer. One of our clients conducted a year-long stability test on the inner lining of our tubes and did not find a single instance of leakage, emphasizing the remarkable reliability of our product.

Aluminum cosmetic tubes for hand cream: Discover the eco-friendly, cost-effective packaging solution revolutionizing the skincare industry. Explore their proven advantages, from product preservation to consumer satisfaction, and why they’re the superior choice for your hand cream product line.”

Why Choose Us as Collapsible Tubes Packaging Supplier

Junsam is a trusted collapsible tube supplier with years of experience in providing high-quality packaging solutions for various industries. It specializes in manufacturing high-quality custom collapsible tubes to cover the various needs of customers.

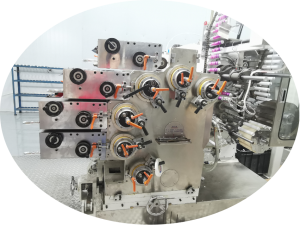

Professional and Advanced Equipment

With more than ten years of experience in product manufacturing. Professional technicians provide you with professional advice. Advanced equipment creates high-quality products for you.

Low Price and High Quality

One stop service can reduce costs and improve quality standards. Arrange from design, material, processing, delivery time, quality inspection and transportation. Reduce any additional costs throughout the process.

Fast and Convenient Delivery

Fast production, early delivery, reliable logistics, can provide door-to-door service. Various transportation modes meet different countries.

Best After-sales Service Provided

Improve product sales and technical after-sales service. 24 hours online video call, actively solve problems for customers

Glance at Collapsible Tubes Workshops & Facilities

After-Sales Support

Our after-sales service is built on a commitment to responsiveness and customization; we guarantee to deliver professional and satisfactory solutions within 12 hours of receiving customer feedback on the collapsible tubes.

Additionally, we pride ourselves on providing targeted services tailored to each client’s unique needs, ensuring a personalized after-sale experience that meets their specific requirements.

Our Market of Collapsible Tubes

Collapsible Tubes FAQs

Toothpaste tubes don’t have a standard length. They come in various sizes, typically measured in volume (milliliters, ml) rather than length. The most common sizes are:

- Standard size: 75 ml (around 2.5 fl oz)

- Travel size: 30-50 ml (around 1-1.7 fl oz)

- Large size: 100 ml (around 3.4 fl oz) or more

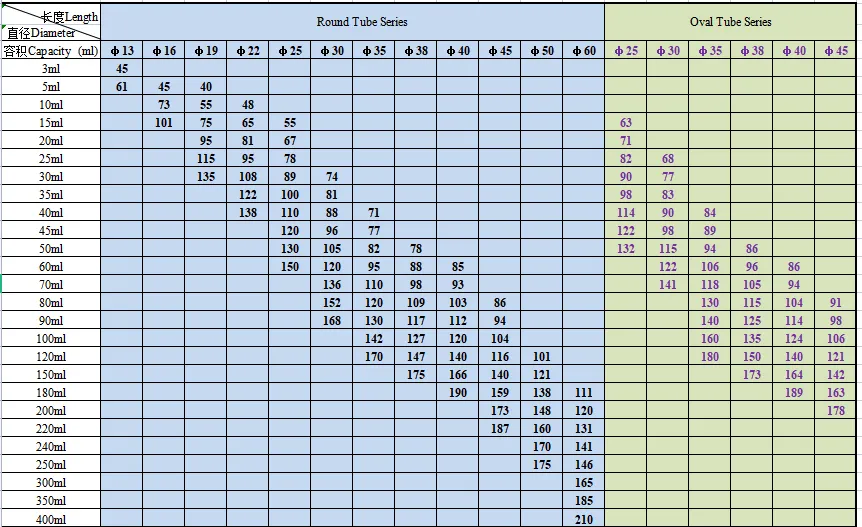

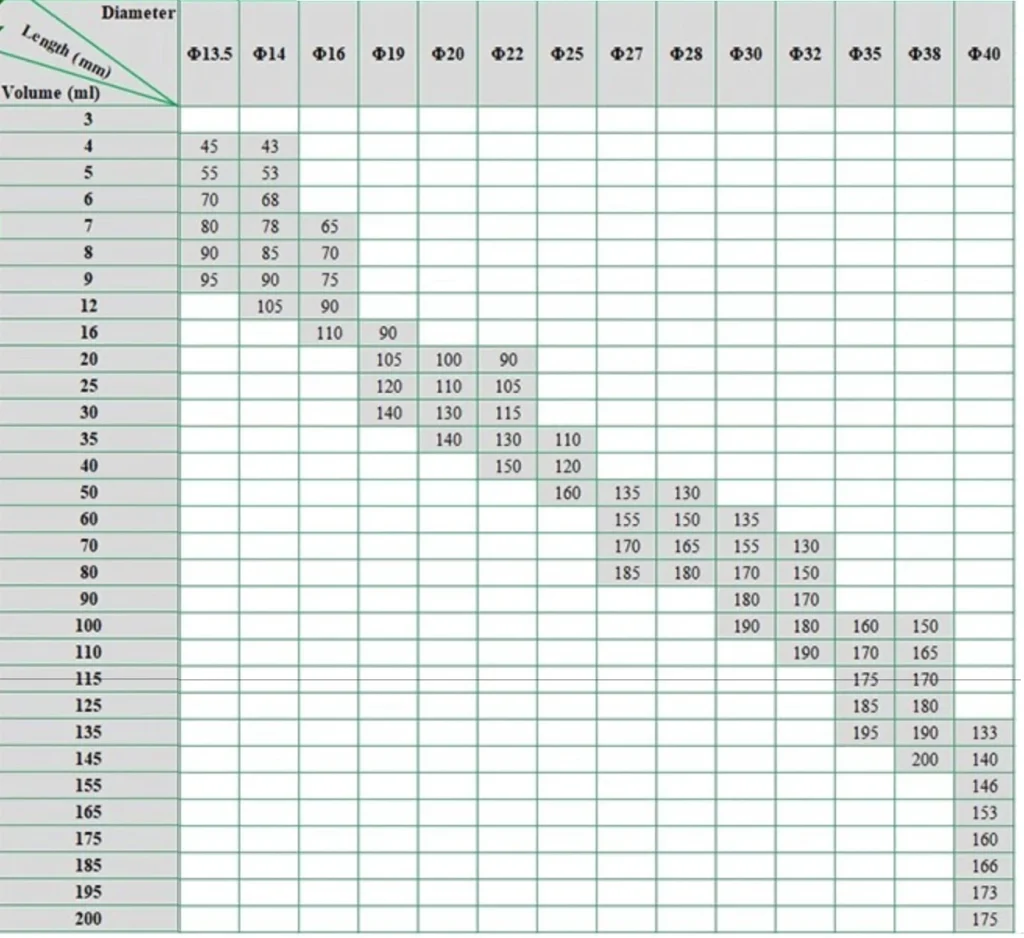

While the volume tells you how much toothpaste is inside, it doesn’t directly translate to the length of the tube. The actual length can vary depending on the tube’s diameter and design. The following table shows typical toothpaste tube volumes, which can help you estimate their diameter and length.

Our greatest advantage lies in our commitment to quality and customer satisfaction. We ensure every product is crafted to meet high standards, and we prioritize responsive, personalized service to meet the unique needs of each client

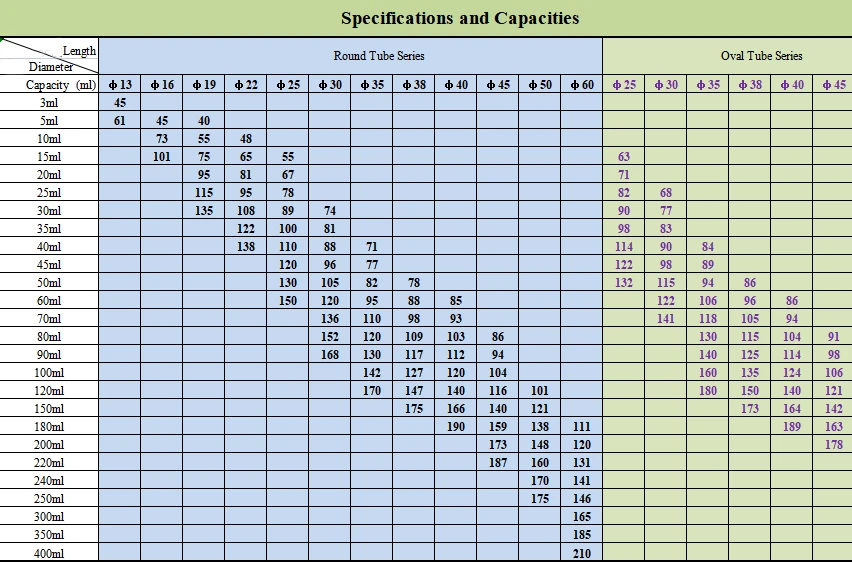

For your guidance, we provide a range of sizes and capacities. However, please note that dimensions may vary slightly depending on the product formulation. We highly recommend conducting a physical test if you are using the tubes for the first time to ensure compatibility

Aluminum Tubes’ Sizes & Capacities:

Plastic Tubes & Laminated Tubes’ Sizes & Capacities

We can provide aluminum tubes, plastic tube and laminated tubes.

Yes, we always print the tubes with custom artworks.

Our aluminum collapsible tubes come with a diverse range of cap options to suit your specific needs and preferences. Below some photos for your review.

These are just part of what we can do, please contact with us for more options.

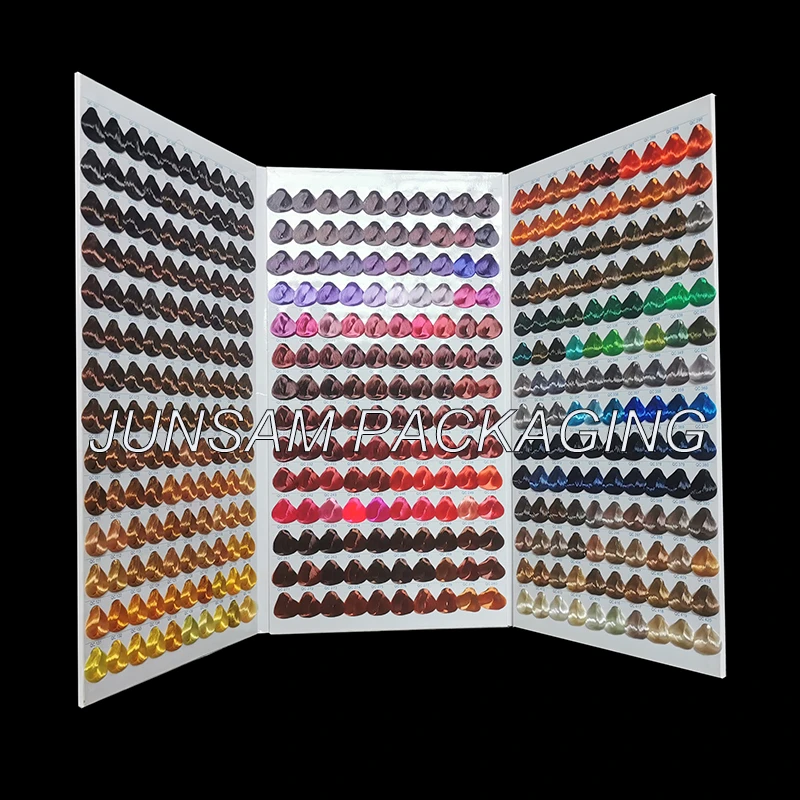

As a collapsible tube packaging manufacturer, our extensive interactions with the cosmetics industry, particularly hair dye producers, have familiarized us with their unique product requirements, which include items like color palettes and folding boxes. Early on, some of our longstanding clients requested that we not only supply tubes but also procure these additional components on their behalf. This process offers substantial benefits, such as ensuring consistency in color tone and quality across all packaging materials. Furthermore, our enduring partnerships with suppliers have led to strong cooperative relations, resulting in advantageous pricing and a high level of cooperation. In summary, by allowing customers to incorporate the purchase of color palettes and folding boxes with their tube orders from us, we effectively address cost control, guarantee delivery timelines, and streamline freight consolidation.

What is the best material for paint tubes?

Aluminum is often considered the best material due to its durability, protective properties, and environmental friendliness.

Why should I choose aluminum paint tubes over other materials?

Aluminum paint tubes offer superior durability, protection, and environmental benefits compared to plastic and other materials.

Can I recycle empty aluminum paint tubes?

Yes, aluminum paint tubes are fully recyclable and can be melted down and reformed without loss of quality.

How do you store paint in aluminum tubes?

Store aluminum tubes in a cool, dry place, away from direct sunlight. Ensure the caps are tightly sealed to maintain the paint’s integrity.

How long do paints last in aluminum tubes?

Paints can last for many years in aluminum tubes, depending on storage conditions and the type of paint.

There are several reasons why plastic toothpaste tubes have become so popular:

- Convenience: Plastic tubes are lightweight and portable, making them ideal for travel and everyday use. They are also easy to dispense toothpaste with just a squeeze.

- Durability: Modern plastic tubes are made from high-quality materials that are durable and can withstand everyday wear and tear.

- Safety: Plastic tubes are a safe way to store toothpaste as they are BPA-free and meet strict safety standards.

Junsam: A Leading Manufacturer of Plastic Toothpaste Tubes

Junsam is a leading manufacturer of plastic toothpaste tubes. We use state-of-the-art technology to create high-quality tubes that are durable, safe, and easy to use. Our tubes are the preferred choice for many toothpaste companies around the world.

Looking Ahead: The Future of Plastic Toothpaste Tubes

As environmental concerns continue to grow, there is a push for more sustainable packaging options. However, plastic toothpaste tubes are still a popular choice due to their convenience and functionality. Manufacturers like Junsam are constantly innovating and developing new technologies to create more eco-friendly plastic tubes.

Conclusion

Plastic toothpaste tubes offer a convenient, durable, and safe way to store and dispense toothpaste. Junsam is a leading manufacturer of high-quality plastic toothpaste tubes. As the industry continues to evolve, we can expect to see even more innovative and sustainable plastic tube options in the future.